Locating The Saw Mill

Locating a good site for a saw mill involved several factors: First, the proposed location needed adequate facilities to bring the raw material to the plant and to transport the lumber to market. It could be by water, rail, or a combination of both.

Second, there had to be a sufficient area of level land to locate the plant. It was recommended that a saw mill producing 100,000 board feet of lumber a day have an area of 25 acres. However, this rule was frequently violated, as inspection of many former mill sites has failed to reveal anywhere near that amount of level ground. The mill owner had to use a great deal of versatility and ingenuity to adopt his mill to the terrain.

Third, there needed to be natural or artificial water storage for the amount of logs necessary for three to four times the mills daily production. Where water was not available, then a roll-way was constructed. The most frequent practice was to dam a small stream to form a log pond. There were many exceptions to this rule; and at many saw mills, the entire tram road and roll-way were elevated to the height of the mills log deck.

Fourth, there must be a well-drained site for the employees living at the mill, and a source of pure water for domestic use and both mill and locomotive boilers. Many mills employed local citizens and had no housing near the mill site, while others constructed complete towns. There were many towns created by the lumbermen, but in general, they were not considered a “company” town, where the mill owner had taken total and absolute control of his employees, such as existed in the mining industry.

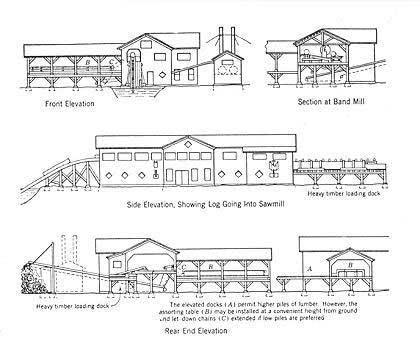

Sawmill Elevation Views

(The American Lumberman)