Waste Disposal

One of the persistent problems within a saw mill operation is the disposal of waste. In the early days, mills were located along streams. The sawdust, edgings, and trimming not used for fuel, were conveyed to the stream, dumped in, and allowed to float away. This lasted until the local populace rose up in arms and demanded another method be found. The most logical use of this waste was fuel for the mill boilers and although the problem was then reduced in size, it was not entirely eliminated.

The most common method of disposal was by burning. The smaller mills conveyed it into piles and set it on fire, regardless of the consequence. The bigger mills sometimes built a fire wall against the prevailing winds and burned the refuse behind it. If they were real fancy, they erected a sheet metal or screen enclosure. The most elaborate was a brick or metal refuse burner. The usual solution was a sheet metal burner.

But burning of useful wood was wasteful, and with all due respect to the great concern about waste today, there was probably far less waste ninety years ago then today. For example, today's saw mills are run by electricity and the use of lath has been replaced by metal or other wall materials.

Many of the mills found the scrap could be used by an auxiliary mill of one type or another. Common in the areas heavily forested with Hemlock was the kindling wood factory. The greatest number of auxiliary mills were lath mills. Others produced box boards, clothespins, insulator pins, and numerous other practical or novelty items from cull lumber and the ever-present small hardwoods.

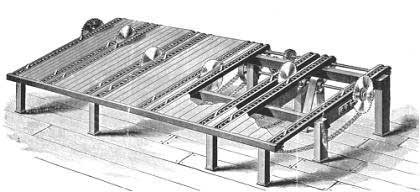

The “refuse” wood had to be reduced to a suitable size for easier handling and the machine frequently encountered for this task was the slasher. It consisted of a table with a battery of saws, similar to the trimmer, only here, the saws did not recede. The scrap was conveyed to the slasher from the various saws in the mill, then transferred across a table with endless chains, similar to the trimmer. The scrap passed through the slasher saws cutting it to the desired length. If the stock was to be used to manufacture lath, the saws were spaced 49 inches apart, furnishing 48-3/4 inch lath stock. All saws were mounted on a common arbor.

Another solution which evolved was the wood refuse grinder, more commonly known as the “Hog”. This machine was fed scrap wood from various locations in the mill and then ground into a size suitable for fuel. After passing through the “Hog”, the ground wood was conveyed to the fuel storage bins, until it was fed to the boilers. The “Hog” was a cylinder mounted on a frame with projecting knives. The number of knives depended upon the use of the material produced by the “Hog”. Refuse could be fed by hand, but it was usually conveyed to the machine and fed by gravity.

Gang Slab Slasher Table

(The Filer & Stowell Company)