The Saw Mill Power Plant

The power plant is the heart of the saw mill operation, for it supplies the power; steam or electric, to operate the machinery within the mill. Again, the size of the power plant depends upon the the installation. A small percentage of the saw mills derived their power by the use of water; but it was the development of steam and its accompanying boiler; which allowed the saw mill to expand to its greatest utilization. Today, steam has been replaced by electricity, or the internal combustion power plant at small mills.

The small circular mills were powered by a simple locomotive-type boiler, very closely resembling the farm steam-traction engine. Occasionally, a small mill would be powered by such a machine. When the mill wasn't operating, the traction engine could be used for other tasks. The small saw mill, with its attendant power plant, was seldom housed in a building, and the only protection afforded from the weather was a roof supported by poles or timbers.

The larger mills had a more complex arrangement. In the beginning, the power plant was located within, or against the saw mill building. This saved a little construction expense, but it was often negated by a stray spark from the stack, setting the mill on fire and destroying the entire plant. The owner's grew wiser, and the power plant (or boiler room) was moved to a separate building, usually of masonry construction. In later years, a few sheet metal buildings were erected.

The power plant contained one or more boilers, depending upon the size of the saw mill; three or four were common. They supplied steam to run the mill engine, pumps, and the steam powered machinery in the mill. Later, a dynamo would be added. The building may have also contained the fuel storage bins.

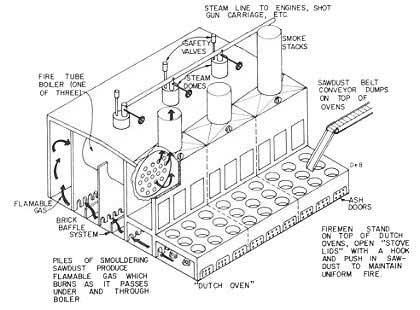

The steam producing equipment consisted of a group of horizontal tubular boilers, or a “Dutch Oven” type boiler. The usual installation consisted of tubular boilers, the number depending upon the total horsepower rating of the machinery in the saw mill plant. A common type was 72 inches in diameter, 18 feet in length, with seventy 4 inch tubes. It produced 150 horsepower at 125-150 pounds steam pressure. These boilers were equipped with grates to burn sawdust and other similar refuse. Firing the boilers consisted of a chute from the fuel storage bins to a hole in the floor, leading to the boiler furnace. The fuel was fed by gravity, occasionally assisted by the fireman, who also regulated the quantity of fuel flow.

Drawing Of A “Dutch Oven” Type Boiler

(Alan Pier)

The mill engine was in the same building as the boiler. It was a single cylinder engine which ranged from a simple slide valve engine, to the compound Corliss engine. This engine drove a flywheel and belt pulley. The belt formed the power connection between the power house and a corresponding belt pulley within the saw mill. This pulley was on a line shaft which ran through the mill. It was from this shaft, containing additional pulleys, that belts led to the individual pieces of mill machinery. With the exception of the carriage and log deck machinery, the mill machinery derived their power from this shaft.

The power house also contained steam driven pumps for water supplied throughout the mill. This room may have contained a dynamo, not to run electric motors, but to supply lighting to the mill, yard, and town, so the saw mill operation could continue around the clock. The use of electricity, to power mill machinery during the railroad logging era was very limited. The mill engineer was in charge of the power plant.