Resaw Mills

The resaw mill converts the cants or timbers from the head saw into smaller sizes, and there were several variations. The sash gang saw, circular resaw, and the band resaw. One of the most frequently encountered types was the sash gang saw.

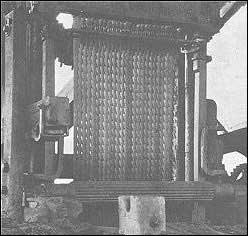

The sash gang saw was a variation of the older sash saw, improved by modern technology into a machine which contained from 18 to 60 saws in the sash frame. The distance between stiles could vary from 34 inches to 60 inches and have a cutting depth up to 24 inches. Cants from the head saw moved by live-rollers to the gang saw and were power fed into the machine. The saws within the sash were commonly spaced to produce one or two inch lumber, but this could vary, depending upon demand. The number of strokes per minute usually was between 225 to 300, with the average length of feed per stroke of 7/8 inches. The production depended upon the size of cants and the number of saws in the sash. There were several other variations of the gang mill. The most notable manufacturer of gang mills were the Wickes Brothers.

24 Blade Sash Gang Resaw

(William G. Edwards)

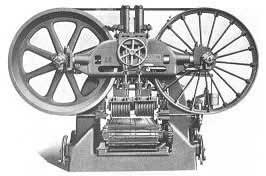

Another resaw used a band saw. They were usually smaller than the head saw and could be mounted vertically or horizontally. There were also double-band resaws. The band resaw advantage was speed, as their feed was 100 feet to 250 feet per minute. Their use could increase the production of a double-band mill by 35,000 board feet or more a day.

6-foot Horizontal Band Resaw

(Prescott-Menomiee)