Log Storage

A log storage area was necessary on the mill site, and could consist of either, water or land storage. For water storage, there needed to be a stream of sufficient size to be dammed or boomed. The frequent method employed was water gained by damming a small stream. Water served two purposes: first, it helped to clean the logs of dirt and stones; second, it was much easier to move a floating log.

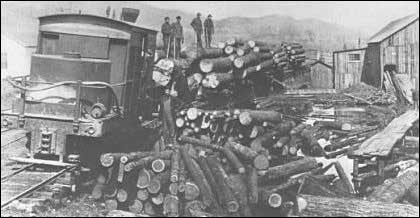

Log ponds varied greatly in size depending upon the area available. The log train arrived along one side, and in some instances, on both sides, on a track inclined to aid rapid unloading of logs from the cars. The early log ponds froze during the winter, and either hampered production or caused the closing of the mill. To overcome this problem, exhaust steam was piped into the pond.

The selection and movement of logs in the pond was under the supervision of the pond tender. He was given instructions as to what timber was needed for the days production, and his men selected the logs and moved them to the jack-slip using long pike-poles. Frequently, floating catwalks or booms, separated certain areas of the pond and the pikemen used these for footing. Often as not, they moved around the pond scampering from one log to the next. The log pond required cleaning at least once a year to remove debris and sunken logs.

Unloading Logs In The Mill Pond

(William Long)

The roll-way was another timber handling method. It could be earth, or logs, laid on the ground perpendicular to the directions of log travel. An elaborate setup elevated the roll-way on piling and timbers. This method was usually restricted to the smaller mills, where there was a shortage of water. Another method, used occasionally, was an overhead-cable-way to lift the logs off the cars onto a pile.