The Log Deck

The log deck provided the storage area where the logs awaited their turn on the carriage. They are inclined away from the jack-slip at a 12 to 15 degree angle, allowing the logs to roll when freed from the jack chain. If it is a single band, or circular mill, the logs enter the side of the mill. In the event the mill has double headsaws, the logs enter in the center, and the log deck is inclined on both sides away from the jack-slip. Some installations use a mechanical log kicker and kick the logs to a particular headsaw, or the selection and kicking of the logs could be accomplished by hand. On double head saw mills, one side usually cut longer logs, such as bridge timbers, and the other side cut the more conventional lengths.

The log deck could include a transfer, using several endless chains with attached log dogs, to crowd the logs toward the log stop. The chains operation could be controlled by the deck leverman. The next piece of machinery was the log stop which had two or more cradle-shaped castings, mounted on a shaft, controlled by the sawyer. In position, the log stop caught the log nearest to the carriage and held it. When needed, the shaft rotated, throwing the log onto the carriage. At the same time, the heel of the casting raised, to prevent a second log from following through. As the stop returned, the following log entered the cradle.

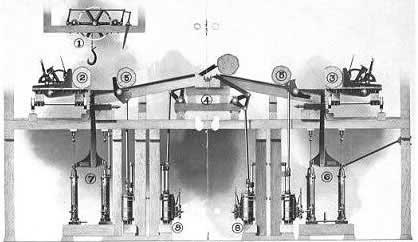

Cross Section Of A Log Deck

(Charles A. Lynch)

The steam-turner was often incorporated in the space between the log deck and carriage. This device is a vertical bar, with teeth pointing upward and powered by two steam cylinders below the mill floor. As steam is admitted to the cylinders, the bar raises, catches the log on the carriage, and turns it to the satisfaction of the sawyer. It can be used before the initial slab is removed, in order to have a preferred face for the first cut, or it can be used to turn the partly-cut log at any time during the cutting of the log. The teeth in the bar are hinged, so the teeth project on the upward and recede on the downward stroke. The steam-turner can also be controlled in a forward or backward direction. In the smaller mills, all work done by the steam-turner was performed by hand. The perfection of the steam-turner was one of the more important developments in saw mill machinery. It greatly increased the speed of loading and turning logs on the carriage, and eliminated considerable physical labor.