Lumber Handling And Transfer Equipment

We have discussed the various pieces of machinery within the saw mill, but have made little mention of how the boards were conveyed from one location to another.

The most common method was the use of various sizes of rollers. Almost all mills used them in one degree or another. The small mill's rollers were simply cylinders mounted on an axle, set into a wooden frame reaching from one location to another. They were “dead” or un-powered, and the boards moved by the workmen pushing them.

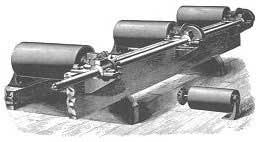

This was entirely unsatisfactory for a large mill. Here the rollers were “live” or powered, either by a line shaft and miter gears to each roller, or by an endless chain. The speed of the rollers closest to the head saw were the fastest, with the speed decreasing as the distance increased through the mill. The framework carrying the rollers could either be wood or steel. The rollers carried the board in line with the head saw. To change line of travel, screw rollers or transfer tables could be used. There was also a limited use of belt conveyors.

Drawing Of Live Rolls

(The Filer & Stowell Company)