The Edger

The object of edging lumber is to remove the wane from the edge of boards; to make them a standard width; to rip pieces into narrower widths; to raise the grade; or to rip cants into edge-grained lumber. Edging machinery is seldom found in the small portable mills, as the waney-edged boards are piled on the head blocks of the carriage and passed by the head saw.

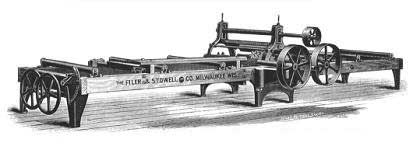

The edger is in line from the head saw and is equipped with several circular rip saws. There are two types; single and double. The double is able to rip two boards of a different thickness at the same time. The feed and press rollers are usually powered; passing the lumber through the machine. The length of feed and tables depends upon the lumber produced by the head saw.

The circular rip saws are mounted on a slotted-arbor by collars sliding in keyways. The number of saws on an arbor varies from two to eight, depending upon the machine size. They can be shifted in a lateral direction by means of a U-shaped guide which fits around the outer edge of the saw below the cutting line. The saws are shifted by either a link-chain arrangement or shifting levers on the smaller machines. The capacity of an edger varies, according to the number of saws and size of material edged. A five saw edger is ample for a single band mill, but with two head saws, an edger is supplied for each head saw. The addition of a gang mill necessitates increasing the size of the edger and is operated by two men: the edgerman who sets the saws and the tail edgerman who picked off the edgings and discarded them.

Right Hand Gang Edger

(The Filer & Stowell Company)